DIE CASTING SERVICES

METAL PARTS MOLDING SOLUTIONS

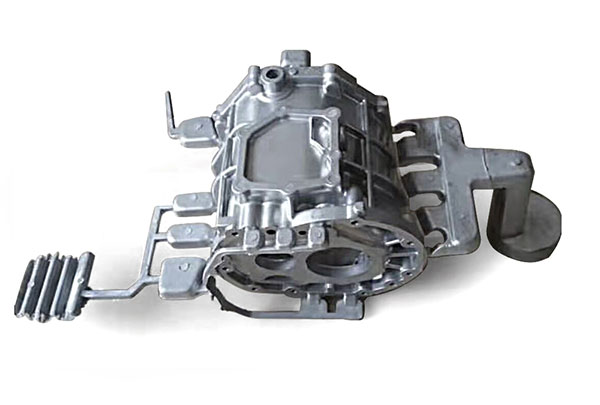

At SMARTTECH we have years of experience producing high-quality die-casted metal parts and components for customers across the globe. Our die casting services are contained all under one roof, streamlining our process and allowing for expedited delivery.

Die casting is the process of shaping metals into specific shapes, referred to as casts. Die casting parts are extremely resistant to heat and corrosion, ideal for applications across many industries including the automotive, aerospace, industrial, and energy industries. Die casting metal parts can be manufactured in incredible array of sizes, and in nearly any shape imaginable.

DIE CASTING ADVANTAGES

- Die casted parts are strong, made of solid metal

- Metal parts can be produced in complex dimensions

- One mould produces thousands of identical casts

- Complex mathematical accuracy

- Brilliant surface finishes available

- Heat, chemical, and pressure resistant

- Efficient and repeatable manufacturing process

- Fastest method for creating metal parts in volume

Even with the incredible number of metal and shape combinations available the process for creating your die casted metal part is simple and easy.

Die Casting Mould Types

light weight, high cost-effective, recyclable, and solid. Die casted aluminum parts can be excellent geometrical shapes, commonly used in automobile and mechanical equipment industry.

super long mould life, high precision dimensions, and various surface treatments. Die casted Zinc products give development advantages for your business. enhance competitiveness

lightest metal, high shock resistance, high strength, excellent thin-walled ability, ultrahigh liquidity, and good dimension stability. It can be die casting to net structure products.

Die Casting Process

The success of your die casting project depends on the quality of the mold tools, and our tool making abilities are unmatched in Asia. After we receive your order, we will:

- Perform a complete Design for Manufacturing review of your CAD files.

- Verify tooling and product raw materials for compliance.

- Use our multi-axis imported CNC machine tools to fabricate the core and cavity.

- Apply careful heat treating to temper the molds.

- Exercise process control when casting your parts.

- Provide any necessary post-machining or processing.

- Professionally inspect and measure finished parts to meet and exceed your specifications.