VACUUM CASTING SERVICES

PROTOTYPING, SMALL BATCH, AND LOW-VOLUME PRODUCTION

SMARTTECH is fully capable of handling your vacuum casting and silicone molding needs. With years of expertise in the field, we can fabricate your parts to the highest standard and with fast turnarounds.

Vacuum casting is a great way to make rigid or flexible parts, and is ideal for prototypes, engineering testing, concept proofing and display demos. These parts can be made from hundreds of casting polymers.

Vacuum casting is a specialized technique for making high-fidelity copies of master patterns using inexpensive silicone molds and pourable casting resins. Copies made in this way demonstrate the same quality as plastic injection molded parts while taking only a fraction of the time and expense to produce.

What is Vacuum Casting?

Vacuum casting is a manufacturing technology that uses a vacuum to draw liquid material into a mold. It differs significantly from injection molding, which pushes liquid material into a mold using a screw.

The process of vacuum casting offers significant advantages, and is particularly useful for parts that have undercuts or fine details.

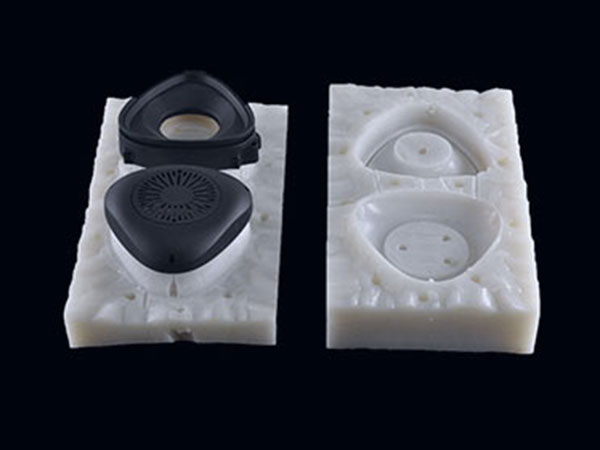

The process starts with a master model, which we creates using one of its CNC machining centers — though 3D printing can also be used. This master model is then immersed in liquid silicone, which is cured and becomes the mold.

Once it has been cut and the master model removed, the silicone mold can be put to use. This stage involves pouring casting resin into the mold, as the vacuum removes bubbles and air pockets to ensure a smooth finish.

The resin part is then cured and removed from the silicone mold, which can be reused around 20 times.Each resin part is an exact copy of the original master model.

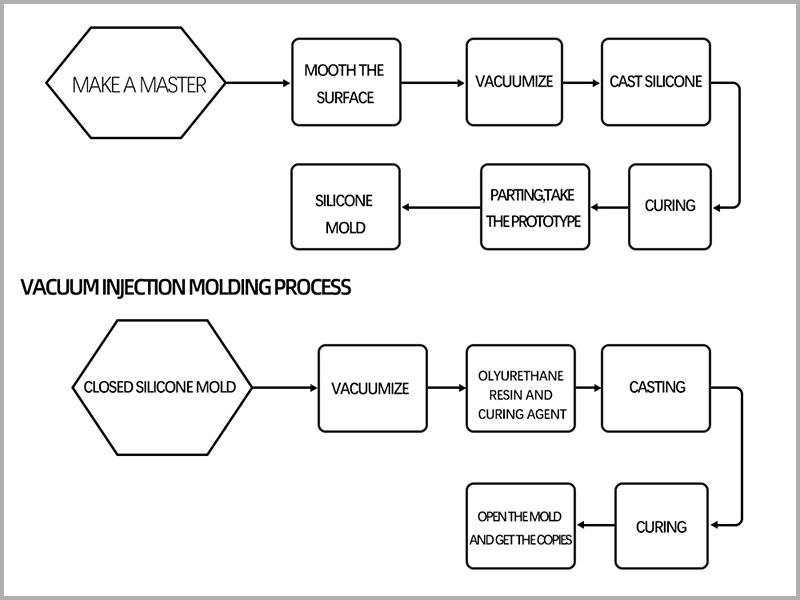

Vacuum Casting Process

Firstly, a silicone is made by putting the prototype in a vacuum environment in which filling it with polyurethane materials so the replica can be duplicated through the process. It minimizes the risks during production and offers advantages, like high efficiency and low cost.

Mold materials: imported silicone, transparent silicone, special silicone.

Product materials: imported PU, transparent PU, soft PU, POM, ABS, PP, PC, high temperature resistant ABS, etc.

Maximum size: 2000 × 1200× 1000mm.

Diagram of vacuum casting molding:

Make a master–Smooth the surface–Vacuumize–Cast silicone–Silicone Mold—Parting,take the prototype—curing

Vacuum Casting Steps

Closed silicone mold—Vacuumize–polyurethane resin and curing agent—Casting—Curing—Open the mold and get the copies