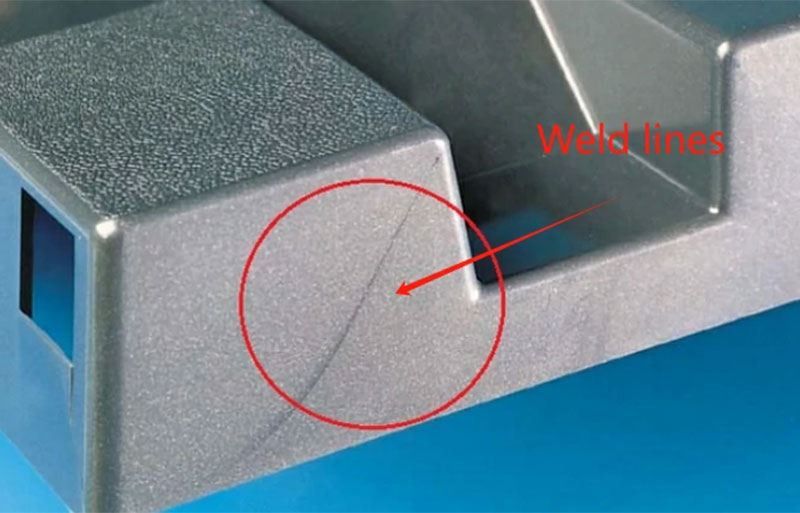

The weld lines in Plastic Injection Molding refer to the surface defect caused by the two streams being welded together.

Causes: If there are holes, inserts, or multi-gate injection molding methods in the fabricated parts or the wall thickness of the parts is uneven, weld lines may be generated.

Remedies:

Material: Increase the fluidity of plastic melt

Mold Design:

(1) Change the position of the gate

(2) Add a venting slot

Process:

(1) Increase the melt temperature

(2) Reduce the amount of release agent