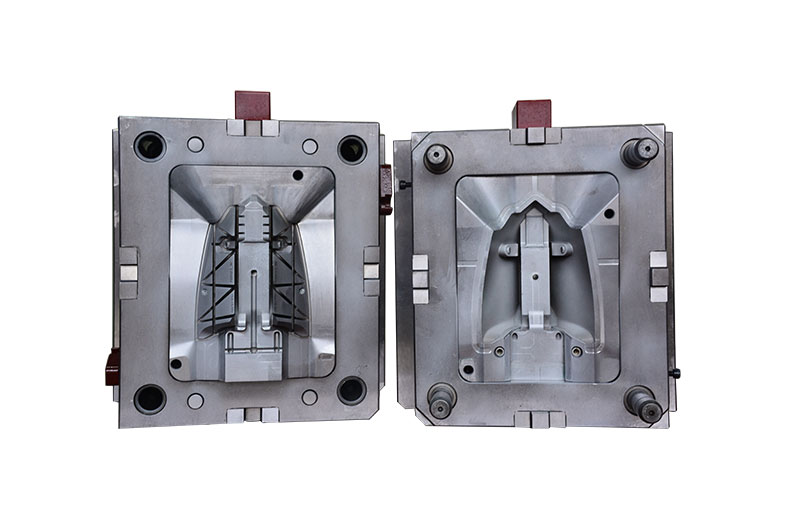

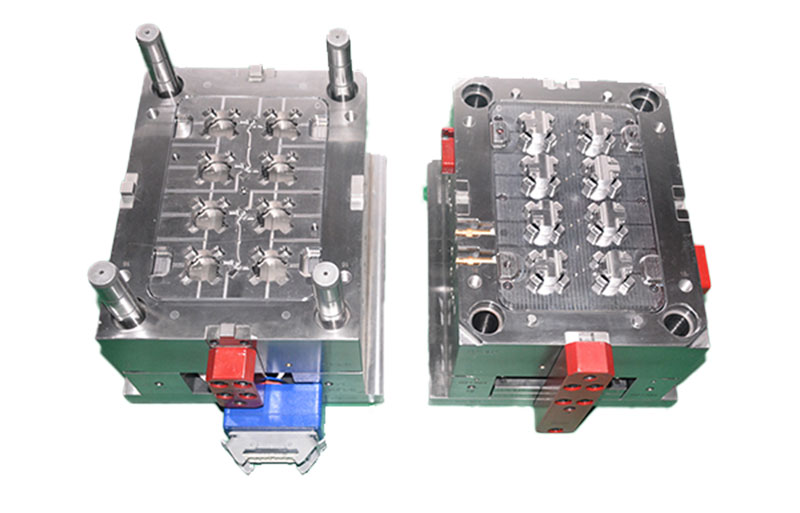

What is precision injection mold

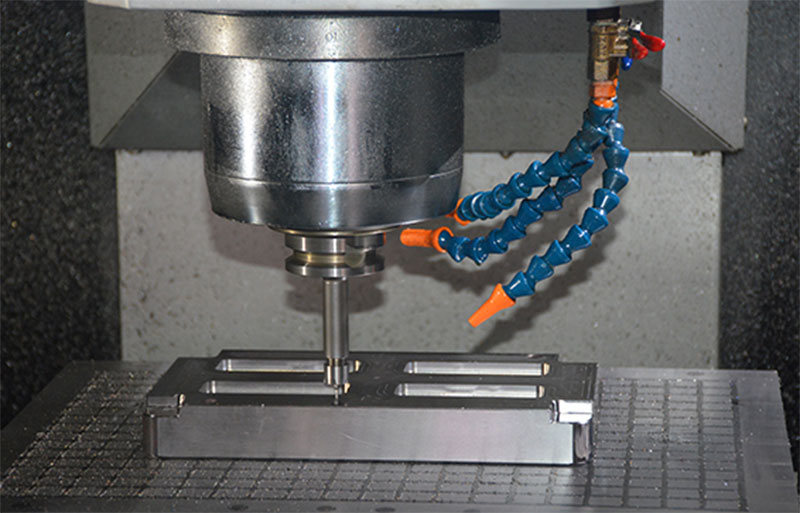

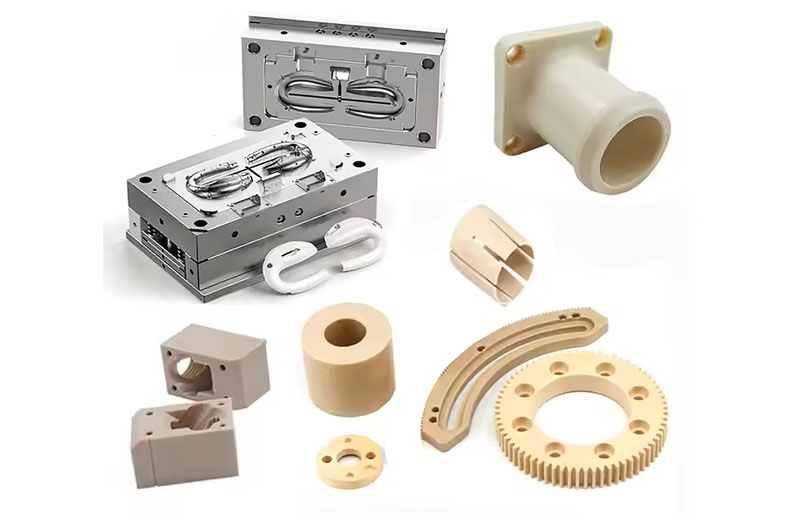

Precision injection mold manufacturing is a high-tech process, which requires the use of precision processing machinery and equipment. The manufacturing process of precision injection mold is necessary to develop precision plastic parts with complex geometry, which can replace high-precision metal parts for various industrial applications. The accuracy of precision injection molds depends on several factors, …