Material cutting

Cut the rolled film into square blocks of the designed size for subsequent printing and molding processes. The precision and dimensions of the cutting are crucial for the smooth progress of subsequent processes;

Offset printing

Create a film screen based on the required icons and text, and print on the cut square film blocks. During the printing process, ensure the uniformity and clarity of the ink to guarantee the decorative effect of the final product;

Ink drying and fixation

Place the printed film in a high-temperature oven for drying, with the aim of fixing the IML ink and preventing it from peeling off or discoloring during subsequent processes;

Apply protective film

To avoid scratching the surface of the printed film during the punching process of positioning holes, it is sometimes necessary to apply a single or double layer of protective film. The selection and application quality of the protective film directly affect the appearance quality of the final product;

Drill positioning holes

According to the requirements of thermoforming, punching of positioning holes is performed on the film. The accuracy and positional precision of the positioning holes are crucial for subsequent thermoforming and injection molding processes;

Thermoforming

After heating the printed film, it is molded using a high-pressure machine or copper mold in a preheated state. During the thermoforming process, parameters such as temperature, pressure, and molding time need to be controlled to ensure that the film can be uniformly and accurately molded into the desired 3D shape;

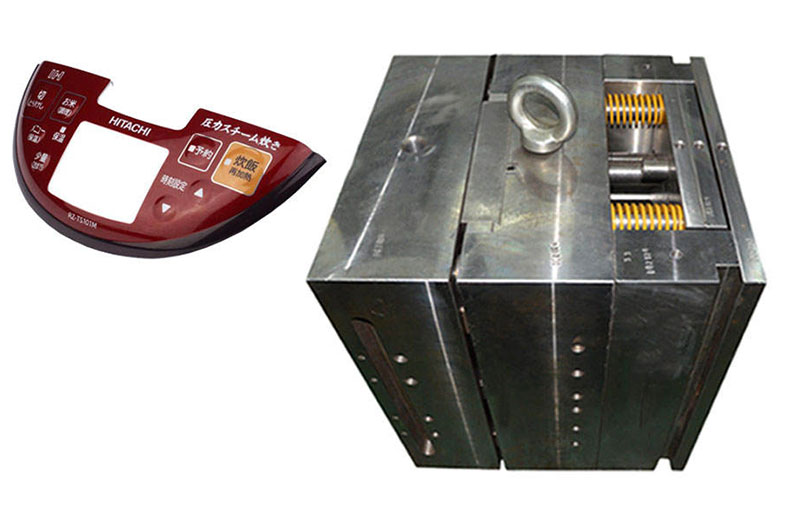

Cutting the peripheral shape

Trim the waste material from the molded three-dimensional film to obtain the final desired film shape. During the trimming process, ensure the flatness and smoothness of the edges to avoid affecting the appearance quality of the final product;

Material injection molding

Place the film, which is molded to have the same three-dimensional shape as the front mold, onto the front mold, and then injection mold the IML finished product. During the injection molding process, it is necessary to control parameters such as injection pressure, temperature, and time to ensure that the resin can fully fill the mold and tightly bond with the film.