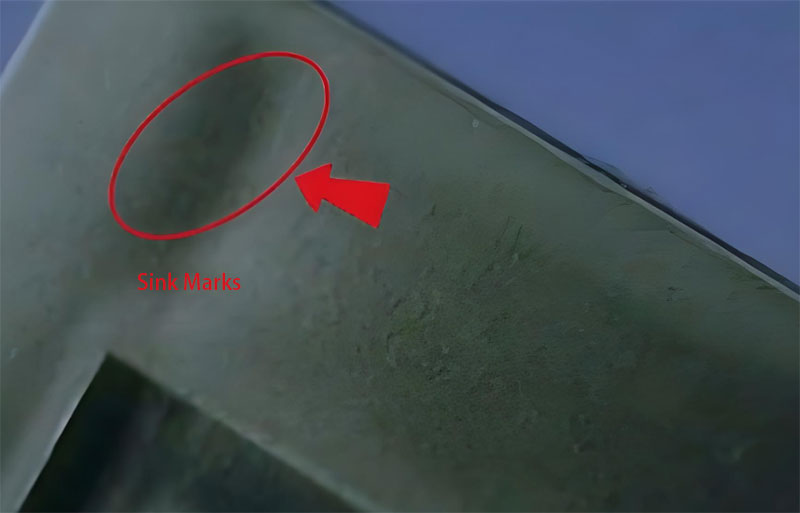

Sink Marks in Plastic Injection Molding is a phenomenon in which the surface of the part is concave at the wall thickness.

Causes:

(1) Injection pressure or holding pressure is too low

(2) The holding time or cooling time is too short

(3) Melt temperature or mold temperature is too high

(4) Improper design of the structure of the parts

Remedies:

Design:

(1) Corrugated surface on the surface where dents are easy to occur

(2) Reduce the thick wall size of the workpiece, minimize the aspect ratio, and the adjacent wall thickness ratio should be controlled at 1.5~2, and try to make a smooth transition. Redesign the thickness of the ribs, counterbore, and ribs. Their thickness is generally recommended as 40-80% of the basic wall thickness.

Process:

(1) Increase the injection pressure and pressure

(2) Increase the gate size or change the gate position