The higher you go in the classification system of surface finishes for mold tools, the more time and effort it takes to produce the finish. In fact, each step of refinement requires first completing the step preceding it. There are no shortcuts here so the costs are additive. Let’s see how each finish is done.

Finishes Created by Polishing

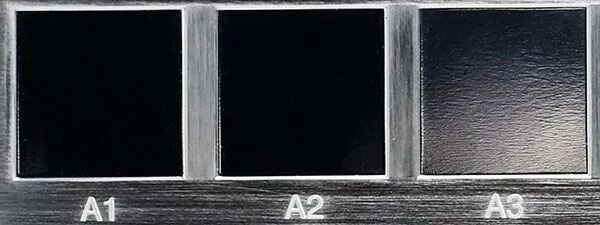

Category A is made with diamond buffing, and is considered to be the highest standard grade, the most shiny or glossy. Part of this is due to the fine grain of the diamond buffing paste, but also some is due to the way it’s applied. A rotary tool polishes the surface in a random, non-linear pattern. This tends to scatter or reflect light without indicating a clear texture. There’s no “direction” to the waviness of the surface, so it looks the same no matter the viewing angle or the angle of light.

There are 3 levels in the A category, representing different degrees of polish, and within these levels an Ra value is specified for each. As an example, A-3 corresponds to Ra 2~3. Surface flatness is a subject unto itself, but this essentially means it’s very flat.

Finishes Made By Sandpaper

Now compare this to Category B, made with sandpaper. This kind of surface finish is applied in a back and forth motion, so it leaves behind characteristic linear scratches producing a very obvious pattern. It’s possible to have an SPI surface finish for B-1 which also measures a flatness of Ra 2~3. But this finish doesn’t look the same as A3, nor would the plastic part made from such a tool.

A B-grade surface finish is considered semi-gloss. It’s fine enough to hide mold defects, tooling and machining marks while being less expensive to produce than A-Grade. These finishes are applied with sanding grit ranging from 600 grit for B-1, 400 for B-2 and 320 grit for B-3.

Finishes Made with Grit Stone

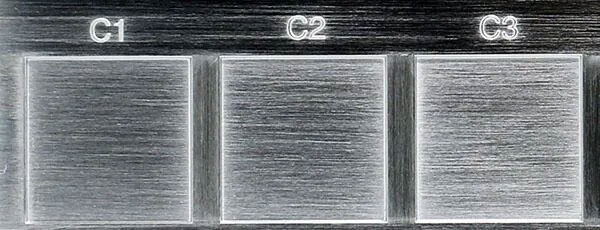

The C-Grade finishes are made with grit sanding stones. As with B-grade finishes the grits of the stones also range from 600 to 320, though they leave behind a surface that is rougher and less flat because the stones are more aggressive in their cutting action. Such a process is used to quickly erase tooling and mold marks and will leave behind a matte surface finish on plastic parts.

Finishes Made By Blasting

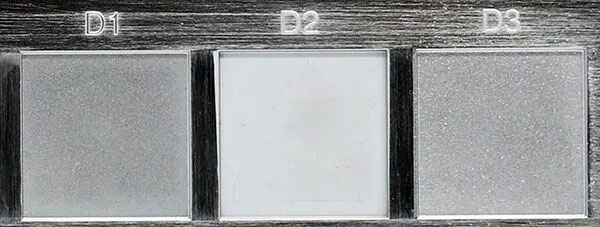

Rougher finishes are made by abrasive blasting with sand or glass beads. These correspond to SPI class D. Because of the random nature of the spraying, the resulting surface finish is uniform and non-directional. This classification is used to produce dull or flat finishes on plastic parts.

Finishes Made with EDM

In addition to these, there are similar results that can be produced using electronic discharge machining (EDM) or spark erosion. We use both approaches depending on the features and the type of metal being processed. Both processes are measured according to the PIA standards.

The top row of 4 examples roughly corresponds to A3-B4 in flatness and finish for injection molding tools, although you can see they are all uniform and without direction. We do not measure the flatness of the bottom row, since these have a surface finish that are rough enough to potentially damage the very sensitive testing equipment.