Injection Molding for Car Battery Cover

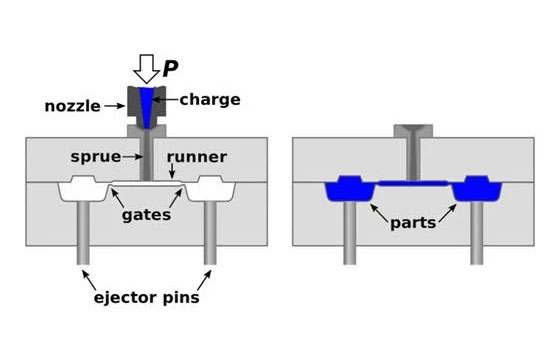

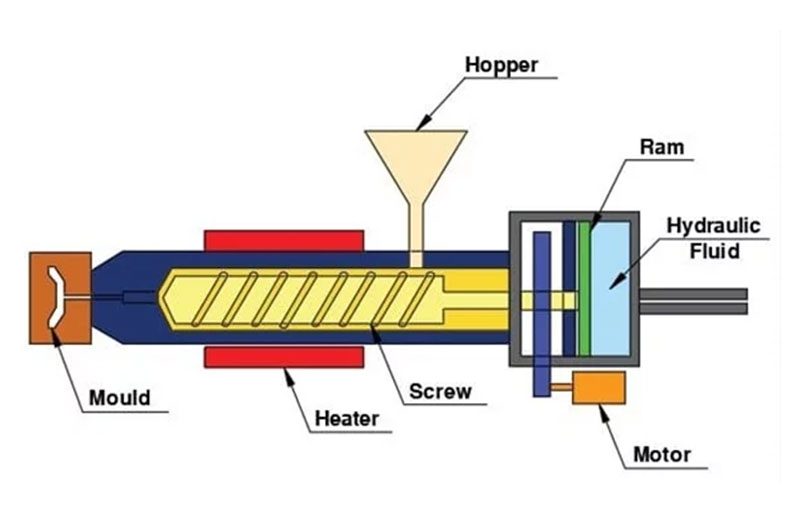

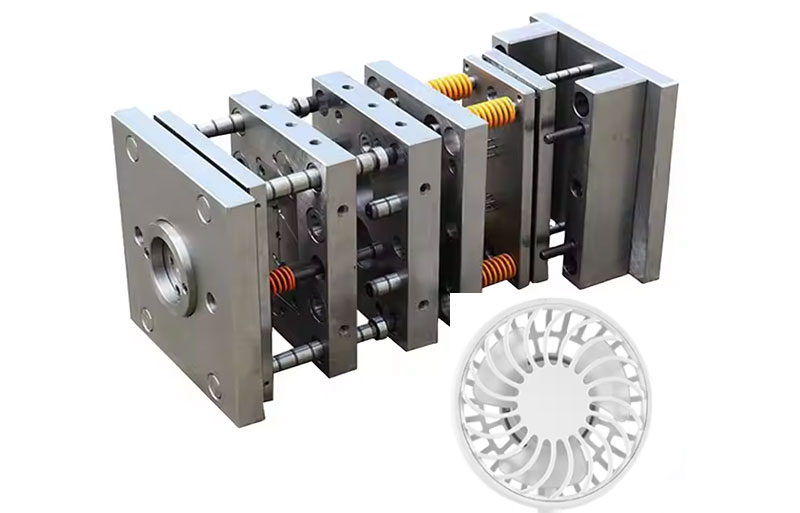

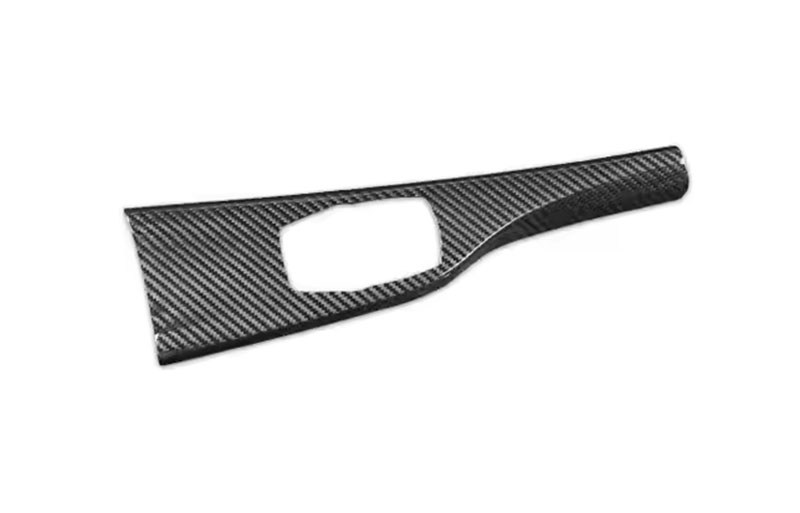

Our company specializes in the injection molding of car battery covers, a critical component in the automotive industry. With years of experience and expertise, we have established ourselves as a leading manufacturer in this field. Our injection molding process for car battery covers involves the use of advanced machinery and precision techniques to ensure the …