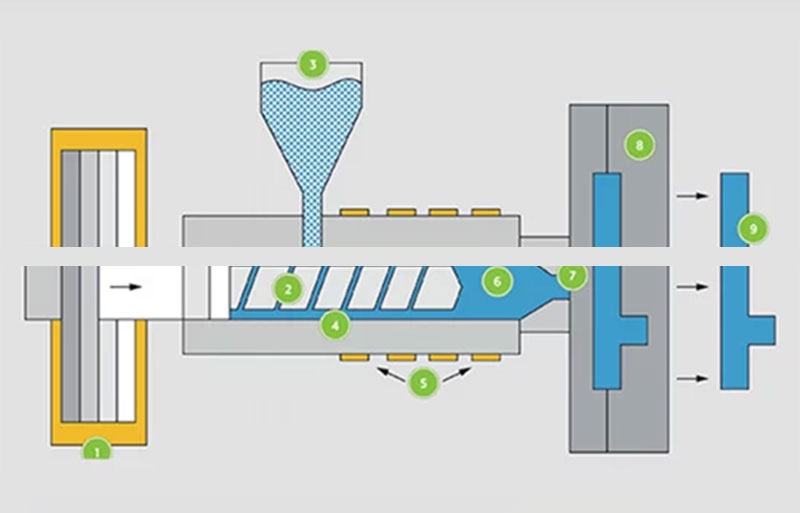

You should first have all the necessary tools for this procedure before kick-starting the plastic injection molding process. All the steps must be followed to ensure you get an accurate finished product. In the first step, the plastic resin which comes in the form of raw granules is desiccated until they have the right levels of moisture in them, and then if fundamental they can be mixed with color shades or masterbatch colors. In the next step, the dried granules are poured into the bowl of the casting machine.

An alternating screw found inside the container of the machine will move these granules towards the direction of the mold. The third step involves mixing and heating the solid particles found inside the barrel to a point where they melt entirely to form a liquid resin. The mold, which is now heated closes spontaneously and the resin, which is under immense pressure, is infused through an opening and into the mold chamber. Cooling is later on done on the mold to harden the inside part after which it opens, and the piece is removed to start off a new series.