The terminology “core” and “cavity” designate two different parts of an injection mold that you can distinguish by their more or less obvious characteristics. For example their appearance, structure, shape, position, or markings. Here is how they are identifiable;

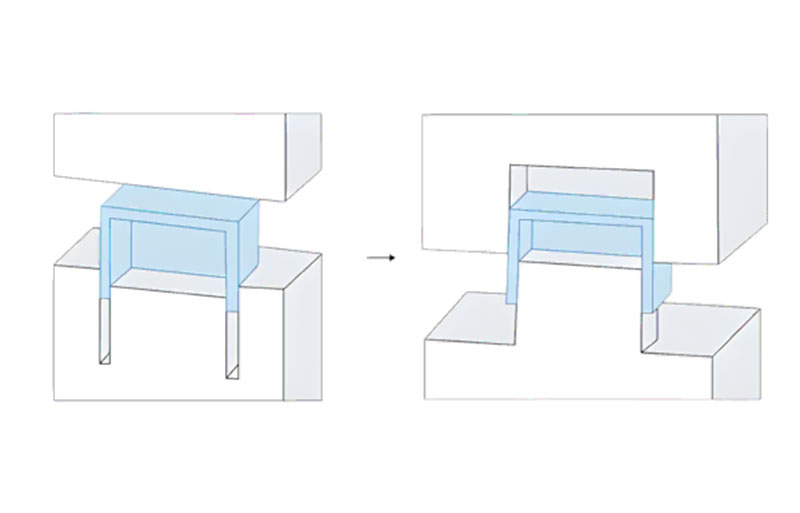

The general look: The core of a mold is the portion of the part tool that is often raised from the cavity and which usually cuts out the holes or recesses of the mold parts. It is mostly seen as a raised or towering in solid form. On the other hand, the cavity in the injection molding die is the cut away or the part that produces the outside looks of a product like its skin or surface. The mold cavity is also understood as an area depressed or hollowed down.

Testing: When the decomposition process of mold occurs, the part tends to stay on the core. Let’s explain this with an example: the core is almost found in the moving side of the mold and the ejection system follows it. In testing, components removed from the die will have a different internal core feature and a cavity external form.

Structure: The core is quite strong and thick as it undergoes molding pressure during its construction. It usually has built-in features like cooling and ejection pins. The cavity plate which is the other half of the stationary mold can afford to be prettier and finer in detail. Because it helps in define the outer contours of the part.

Shape and Position: The mold’s core is located on the moving side, and it is dense, solidly axial, and typically extends in cylindrical or conical shapes to create internal features for the component. When viewed from the other end of the stationary half, the injection molding cavity is relatively wider and deeper to give the exterior shape to the component. The boundary between the mold core and the cavity is the parting line.

Markings and Others: Cores and cavities are usually identified using numbers or marks. For example, ejection pin marks identify the core side. Cavity sides are however less detailed and are usually made smooth, have embossed names and part numbers on external surfaces of the component.