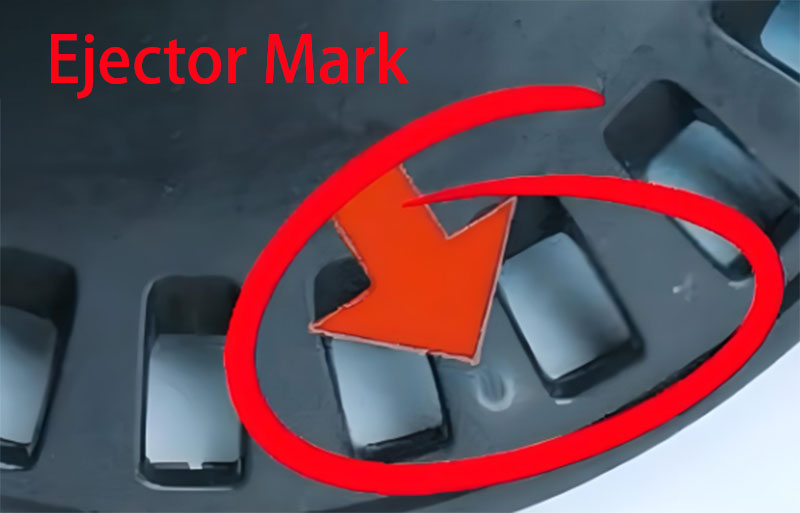

This defect is mainly characterized by excessive force on the plastic part during ejection, resulting in prominent white marks on the ejection area of the plastic product, possibly accompanied by frost-like fine cracks. Ejector mark issues typically occur on the surface of the plastic injection molding part, especially where the ejector pin is located on the ejection side of the mold, leading to stress whitening and increased stress.

Causes of Ejector Mark

Holding pressure time too long or too short.

Insufficient mold draft angle.

Rough surface in the demolding direction.

Vacuum forming on one side of the ejector.

Inadequate cooling time.

Insufficient contact area between ejector pins and plastic parts.

Remedies for Ejector Mark

Adjust holding pressure appropriately.

Increase the draft angle for demolding.

Polish the mold surface in the demolding direction.

Adjust ejector pin positions, placing ejector devices at locations with appropriate wall thickness.

Increase the cross-sectional area of the ejector rod end.