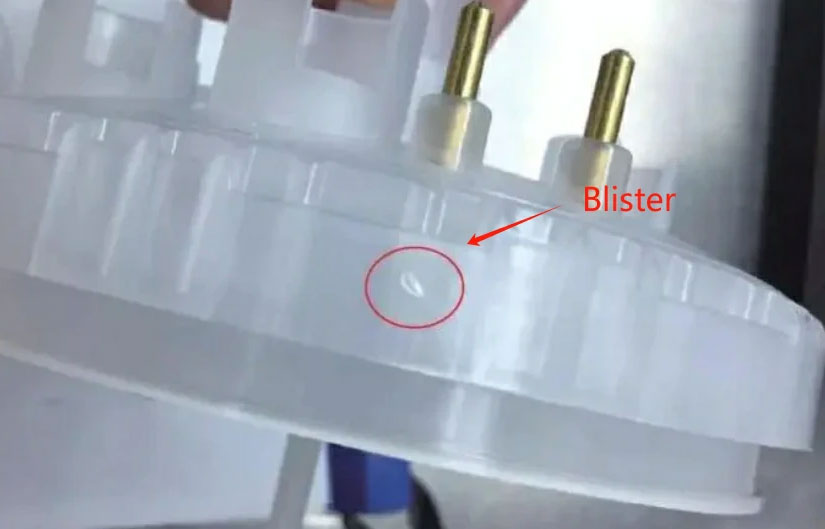

This type of defect typically manifests as numerous very small blister within the finished product, often accompanied by silver streaks. When observing the product externally, these blister typically appear as circular bright spots.

For precision plastic injection molding products with waterproof performance requirements, even a tiny blister can lead to the entire product being returned and customer complaints in severe cases. Especially in transparent products, the presence of blister can significantly affect their aesthetics.

Causes of Blister

Poor design of product thickness, resulting in local overthickness.

Plastic not properly dried or absorbs moisture from the atmosphere.

Low injection pressure and short holding time, causing the molten material not to adhere closely to the mold cavity surface.

Insufficient or blocked venting on the mold parting surface.

During screw pre-plasticization, too low back pressure and too high screw speed result in the screw retracting too quickly, allowing air to be easily pushed forward along with the material to the front end of the barrel.

Injection speed too fast, causing shear-induced decomposition of the molten plastic and gas generation.

Unreasonable mold design, such as poor gate positioning, too small gates, narrow runners, and unreasonable mold cooling system resulting in too large temperature differences in the mold, causing discontinuous flow of the melt in the mold cavity, blocking the passage of air.

Remedies for Blister

Adjust gate positioning and runner size to minimize mold temperature differentials.

Use pure raw materials and design products with uniform wall thickness as much as possible.

Adjust injection speed according to the product structure.

Decrease screw rotation speed.

Avoid jetting.

Increase injection pressure and extend holding time.