Why is Cooling So Important for Plastic Injection Molding

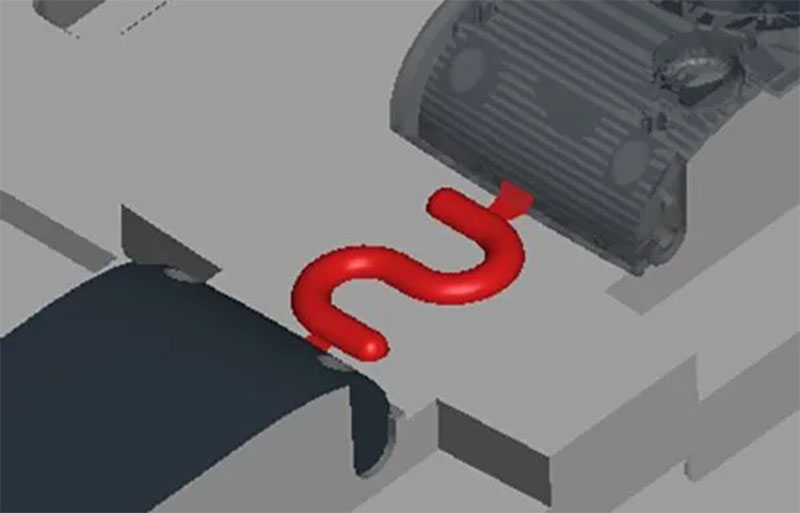

Cooling is a critical phase in plastic injection molding, directly influencing production efficiency, product quality, and cost-effectiveness. Accounting for 60–75% of the total molding cycle, its optimization is pivotal for manufacturers aiming to balance speed and precision. In conclusion, cooling is the linchpin of injection molding success. It bridges productivity, quality, and sustainability, making its …

Why is Cooling So Important for Plastic Injection Molding Read More »