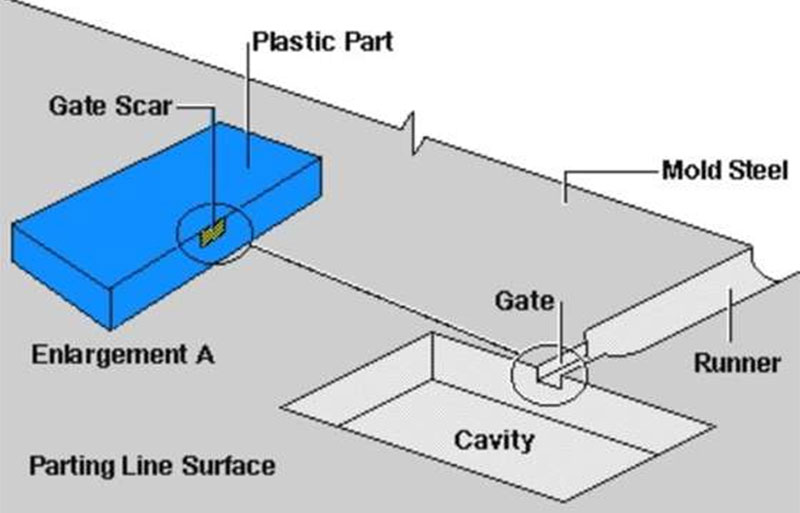

Why Do You Need Injection Mold Gate Design?

An injection molding gate design directly affects the outcome of a plastic mold. A well-designed gate manages the volume and direction of the molten plastic that flows into the mold. This is because you wouldn’t want molten plastic flowing toward the runner/nozzle instead of the mold. In addition, the mold gate design ensures that the …