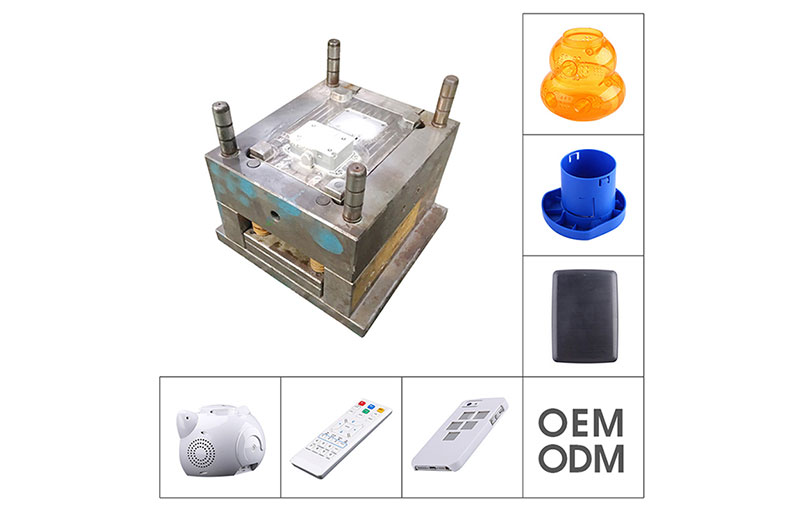

Low-Volume Production Rapid Injection Molding

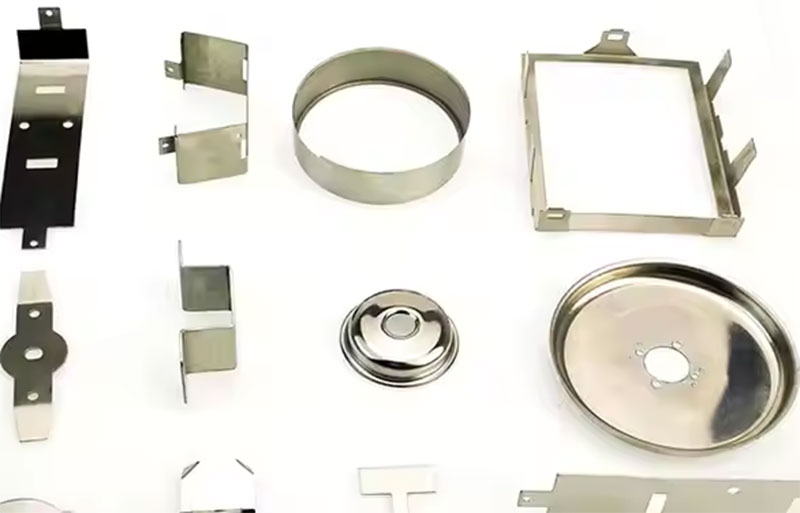

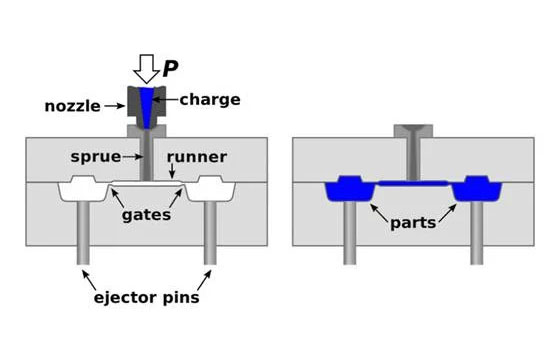

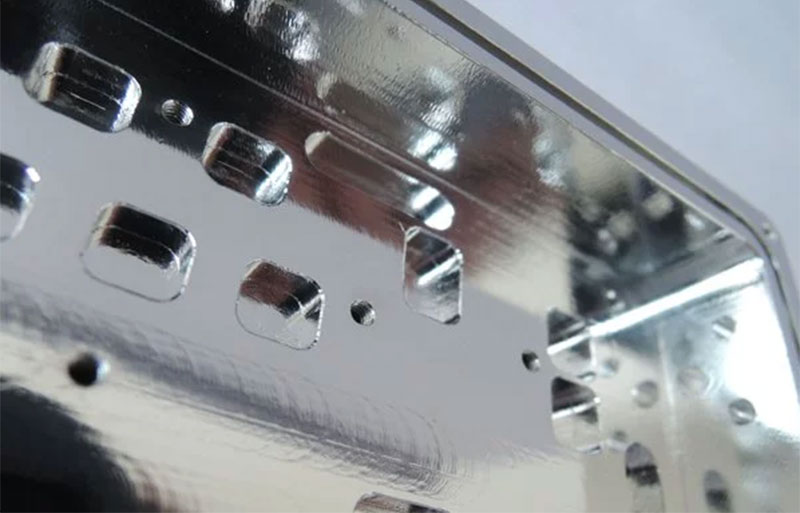

Our company specializes in Low-Volume Production Rapid Injection Molding, a cutting-edge manufacturing process tailored for producing high-quality parts in limited quantities. Injection molding, also known as injection moulding, is a widely used manufacturing process for plastic and metal materials. It involves injecting molten material at high pressure into a closed mold, which then cools and …