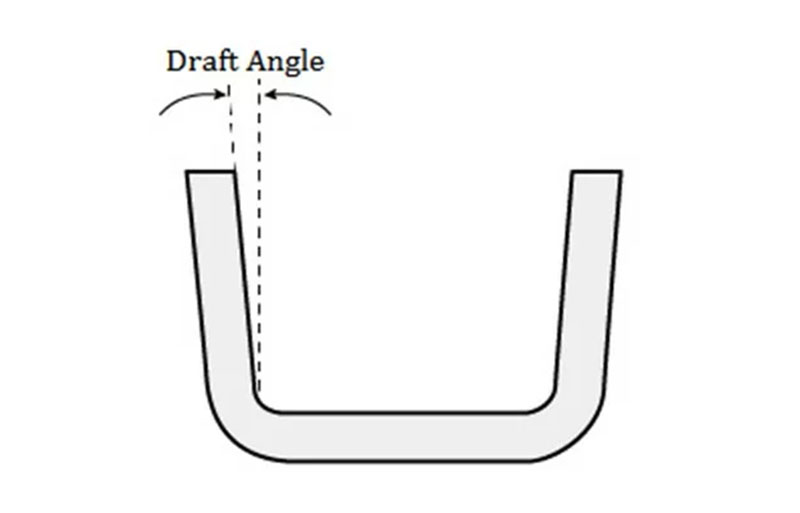

What is Draft Angle in Injection Molding

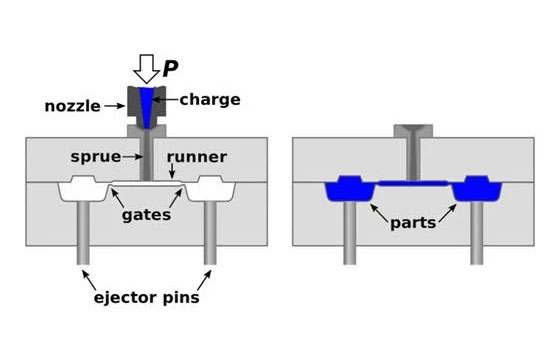

Injection molding is one of the most popular methods for rapid manufacturing. The injection molding draft angle is a critical parameter in this process that has a significant impact on product quality. The injection molding draft angle is an essential geometric feature built into molds for injection molding. It is the taper, or degree of …