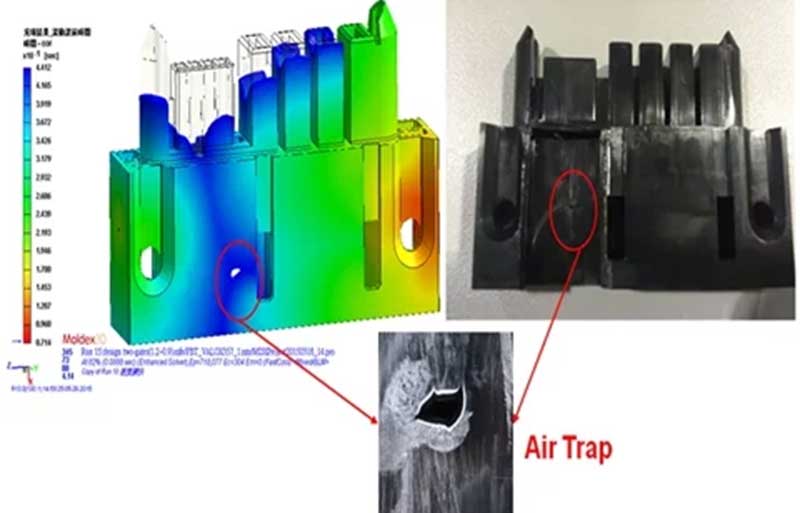

Air traps are where air is trapped in the cavity to create bubbles in the part during plastic injection molding.

Causes: It is caused by the air being unable to escape from the parting surface, the ram, or the vent when the two melt fronts meet.

Remedies: Structural design: Reduce thickness inconsistency and try to ensure uniform wall thickness

Mold design:

(1) Add a vent at the last filled place

(2) Redesign the gate and runner system

Process:

(1) Reduce the injection speed of the last stage

(2) Increase the mold temperature