In the field of injection molding processing, flashing is a common quality defect, manifested as excess thin-flake-like plastic appearing at the edges or parting lines of plastic parts. This problem not only affects the appearance of the product but may also lead to difficulties in subsequent assembly or even functional failure.

I. Core Causes of Flashing

(A) Material Factors

1. Abnormal Melt Viscosity

- Low viscosity: Low-viscosity materials such as PE and PP have low flow resistance and are prone to seeping into mold gaps.

- High viscosity: Highly filled materials (e.g., glass-fiber-reinforced nylon) experience significant pressure loss during flow, causing a sudden increase in cavity pressure.

2. Moisture Absorption and Impurity Effects

- Moisture-absorbent resins: If moisture-absorbent resins like PA and ABS are not fully dried, the vaporization of water increases cavity pressure, breaking through the parting line.

- Impurities in the mix or blending of different resin grades: This can lead to uneven plasticization of the melt and uncontrolled local pressure.

(B) Equipment Factors

1. Insufficient or Imbalanced Clamping Force

- Improper equipment selection: The clamping force calculation formula is F = P × A (where P is the cavity pressure and A is the projected area of the plastic part). Equipment is not matched according to the size of the plastic part.

- Parallelism deviation of the mold platen: Uneven force on the tie bars causes local gap expansion during mold closing. For example, in one case, when the parallelism error of the mold platen exceeded 0.1 mm, the flashing incidence increased by 40%.

2. Wear of the Screw/Melt Barrel

- Excessive clearance (> 0.5 mm) causes melt retention and degradation, while also failing to transmit pressure effectively during injection. This requires an increase in injection pressure for compensation, indirectly increasing the risk of flashing.

(C) Uncontrolled Process Parameters

1. Imbalance between Pressure and Speed

- Excessive injection pressure: If the pressure is not reduced in time during the packing stage, the static pressure in the cavity exceeds the clamping force (e.g., the risk significantly increases when the packing pressure exceeds 80 MPa).

- Excessive injection speed: High-speed shear heating reduces melt viscosity and shortens cooling time, leading to an excessively high peak filling pressure.

2. Improper Temperature Control

- Excessive barrel temperature: Thermally sensitive materials (e.g., PVC) degrade from overheating, causing a sudden drop in melt viscosity and easy overflow from the parting line.

- Excessively low mold temperature: Rapid cooling of the melt reduces fluidity, requiring an increase in injection pressure for compensation and increasing the probability of flashing.

(D) Mold Factors

1. Wear and Fit Defects of the Parting Line

- Long-term production causes an increase in the roughness of the parting line (Ra > 0.8 μm), or wear of the mold locating pins (clearance > 0.03 mm), resulting in sealing failure during mold closing.

2. Failure of the Venting System

- Blocked or inadequately designed venting slots (e.g., depth < 0.02 mm) cause trapped air, leading to a sudden increase in cavity pressure. For example, in the case of a mold for an automotive component, the flashing incidence increased from 1% to 8% due to poor venting.

3. Imbalanced Runner System in Multi-Cavity Molds

- Inconsistent runner lengths and cross-sections lead to overfilling of some cavities. For example, when the length difference of runners in a two-cavity mold exceeds 15%, the risk of flashing in the distant cavity increases.

II. Step-by-Step Solutions to the Flashing Problem

(A) Optimization of Material Preprocessing

1. Precise Drying Process

- PA66: Dry at 120°C for 4–6 hours, with a moisture content < 0.05%.

- PC: Dry at 120–130°C with forced air circulation for 8 hours, with a moisture content < 0.02%.

2. Standardized Mixing Management

- Use a loss-in-weight mixing feeder with an error ≤ 0.1%. When mixing different-colored materials, thoroughly clean the barrel to avoid contamination.

(B) Equipment and Mold Maintenance

1. Clamping Force Calibration and Mold Platen Maintenance

- Regularly detect clamping force attenuation using a pressure sensor and adjust it if the error exceeds 5%.

- Monthly check the parallelism of the mold platen and calibrate it using a laser interferometer to ensure an error < 0.05 mm/m.

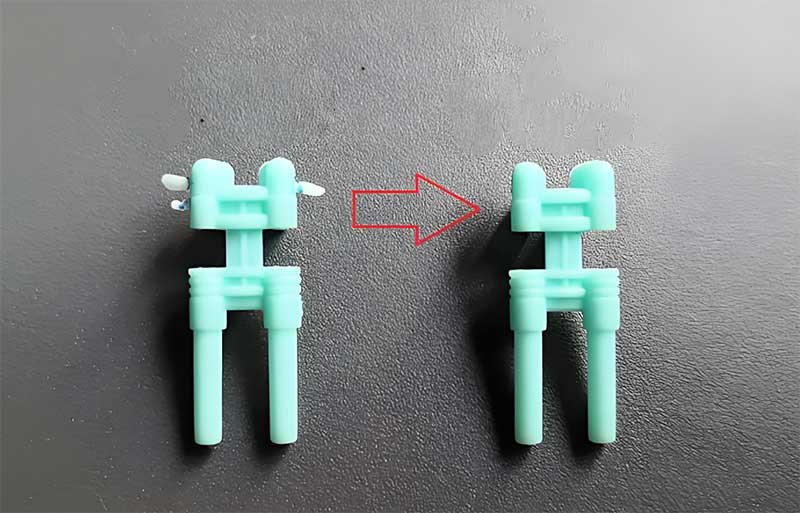

2. Repair of the Mold Parting Line

- Repair worn areas using electrical discharge machining (EDM) and grind the mating surface to Ra ≤ 0.4 μm.

- Replace the locating mechanism (guide posts/guide bushings) when the wear exceeds 0.02 mm to ensure mold closing accuracy.

(C) Fine-Tuning of Process Parameters

1. Segmented Pressure-Speed Control

- Filling stage: Use high speed (80–100 mm/s) for rapid filling to avoid premature cooling of the melt.

- Packing stage: Switch to low speed (20–30 mm/s) and reduce the packing pressure to 60–70% of the injection pressure (e.g., if the injection pressure is 100 MPa, set the packing pressure to 60–70 MPa).

2. Temperature Gradient Optimization

- Barrel temperature control: Use a three-stage temperature control (feeding section 180°C → compression section 220°C → metering section 240°C), with the nozzle temperature 10°C lower than that of the barrel.

- Mold temperature control: Adjust according to the material, e.g., ABS mold temperature 50–70°C, PC mold temperature 80–100°C, with a temperature difference controlled within ±3°C.

(D) Improvement of Mold Structure

1. Venting System Upgrade

- Add φ1–2 mm venting holes at the end of the main runner and open 0.03–0.05 mm deep venting slots on the parting line, spaced 50–100 mm apart.

- Use vacuum-assisted venting to reduce cavity pressure to below -0.06 MPa, minimizing pressure increases caused by trapped air.

2. Balanced Runner Design

- Use a hot runner system for multi-cavity molds to ensure a filling time difference of < 5% between cavities.

- For cold runner molds, arrange them symmetrically and allocate the runner cross-sectional area proportionally according to the number of cavities.

III. Construction of a Preventive Management System

(A) First-Article Three-Inspection System

- Continuously take 5 samples at the beginning of production and check the flashing thickness at the parting line (standard ≤ 0.02 mm) using a secondary element imaging instrument.

(B) Equipment Health Records

- Establish a wear curve for the screw/melt barrel and check the clearance every 500,000 production cycles. Replace it if the clearance exceeds 0.3 mm.

- Record the production count in the mold history sheet and conduct a comprehensive flaw detection test every 200,000 cycles.

(C) Intelligent Monitoring System

- Install pressure sensors to monitor cavity pressure in real time and set an alarm value (e.g., when exceeding 80% of the clamping force).

- Analyze the correlation between the flashing incidence and process parameters through an MES system and establish a predictive model.

IV. Typical Case Analysis

A home appliance company encountered a 5% flashing defect rate when producing ABS air conditioner panels. After investigation, the following causes were identified:

- Causes: Worn mold parting line (Ra = 1.2 μm), insufficient clamping force (theoretical requirement 1500T, actual use 1200T), and excessive packing pressure (80 MPa).

- Solutions:

- Grind the parting line to Ra = 0.4 μm and replace the guide posts and guide bushings.

- Upgrade the equipment to 1800T clamping force and reduce the packing pressure to 50 MPa.

- Use segmented injection speed (filling stage 90 mm/s → packing stage 25 mm/s).

- Results: The flashing defect rate dropped to 0.8%, and production efficiency increased by 12%.

Conclusion

Controlling flashing in injection molding is a systematic project that requires full-chain management from material properties, equipment precision, process optimization, to mold maintenance. Establish a closed-loop management system of “prevention-detection-improvement” and build a process parameter database through regular equipment calibration, mold fine maintenance, and process parameter database construction to achieve precise prevention of flashing defects. Only by controlling the tolerance of each link at the micrometer level can the quality stability of injection-molded products be fundamentally improved.

Technical Tip: When the flashing problem recurs, prioritize the troubleshooting path of “mold-equipment-process” to avoid excessive adjustment of process parameters, which may lead to the derivation of other defects. Regularly participate in industry technical seminars to learn about the latest mold coating technologies (e.g., diamond-like carbon coating, DLC) and intelligent injection molding equipment, which can further enhance flashing control levels.