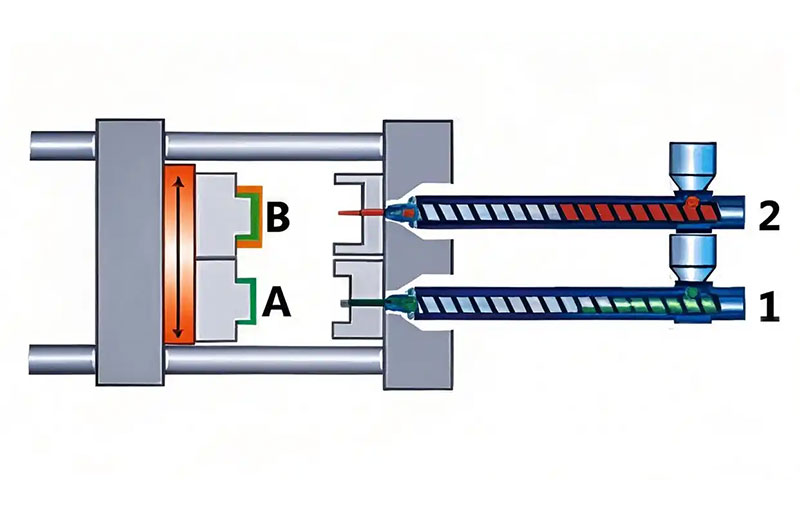

First shot (substrate molding): Using the first injection unit of a two-shot injection molding machine, melt rigid engineering plastics (such as PC, ABS, or PP) and inject them into the first mold cavity to form the substrate part of the product.

Mold core rotation or mold switching: After the first shot, the male mold separates from the first female mold, but the finished product does not eject. By means of rotation (180° or 90°) or slider indexing, the substrate is precisely aligned to the second cavity in preparation for the second shot

Second shot (cladding or decorative layer injection molding): The second injection unit injects another molten material (such as TPU, TPE, or different colored PC/PMMA) into the second cavity of the same mold, completing the molding of the cladding, decorative, or functional layer.

Pressure maintaining, cooling, and ejection: During the pressure maintaining stage, material shrinkage is compensated for, followed by cooling, and finally, the mold is opened to eject the two-shot injection molding part with the two materials integrated.