Designing a manufacturing tool involves multiple stages. Teams can follow this workflow:

- Concept Development. Designers sketch tool geometry and features.

- Material Selection. Engineers choose raw material and coatings.

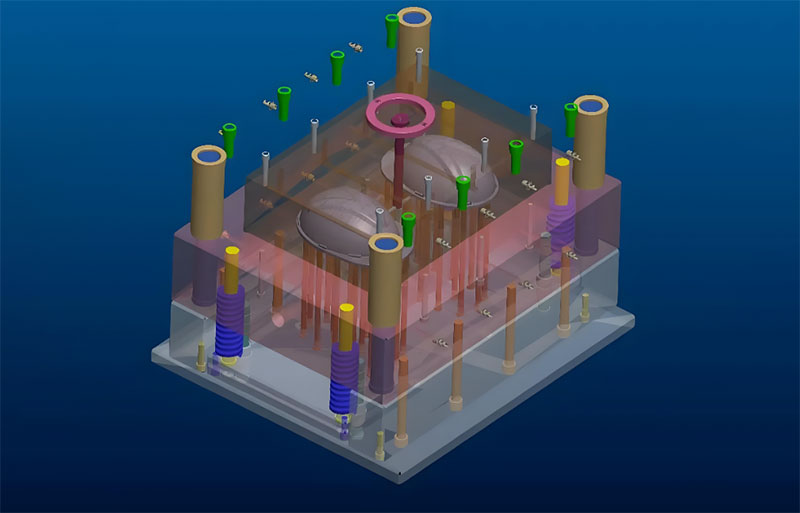

- CAD Modeling. The team builds a 3D model for simulation and review.

- Simulation & Analysis. Software tools predict stress points, cooling efficiency, and fill patterns.

- Prototype Tooling. A soft tool (e.g., aluminum mold) validates part design.

- Final Tool Fabrication. The team machines the hardened tool and applies coatings.

- Testing & Commissioning. Engineers run first‐article inspections and adjust as needed.

- Production & Maintenance. Technicians schedule routine inspection, repair, and reconditioning.

Throughout this tooling design process, clear communication between designers, manufacturers, and end users helps manage expectations on cost, timing, and performance.