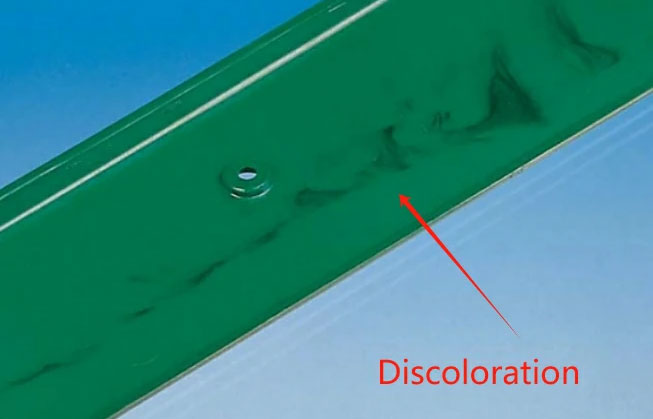

When the color of plastic molded parts is incorrect, it directly leads to uneven color or significant differences in color depth within a product or batch of products. This discoloration typically occurs in specific stripes on the molded product and is manifested as color differences, jetting marks, black spots, or impurities.

Causes of Discoloration

The material is contaminated, with high moisture and volatile content.

The mold gate is too small, affecting the flow and fusion of the plastic.

The equipment is not cleaned properly, with dust or other particles deposited in the hopper, leading to contamination and discoloration of the raw material.

Remedies for Discoloration

Regularly clean equipment.

Select appropriate gate sizes based on product requirements.

Choose high-quality materials to ensure purity and dryness.

Avoid using expired or low-quality colorants and additives.