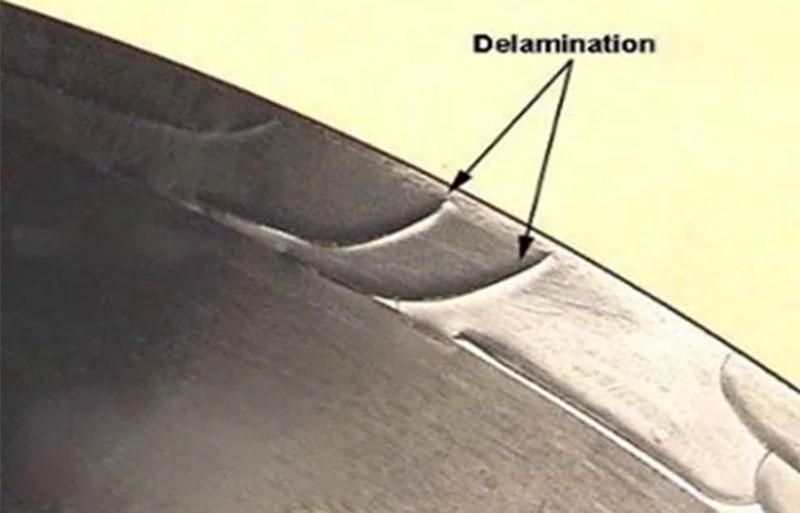

It refers to the surface of the part that can be peeled off layer by layer.

Causes:

(1) Mixing other incompatible polymers

(2) Excessive release agent used during molding

(3) resin temperature is inconsistent

(4) Excessive moisture

(5) The gate and the flow path have sharp angles

Remedies:

Material: Avoid incompatible impurities or contaminated recycled materials mixed into the raw materials

Mold design: Chamfer all runners or gates with sharp angles

Process:

(1) Increase the barrel and mold temperature

(2) Appropriate drying of the material before injection molding

(3) Avoid using too many release agent