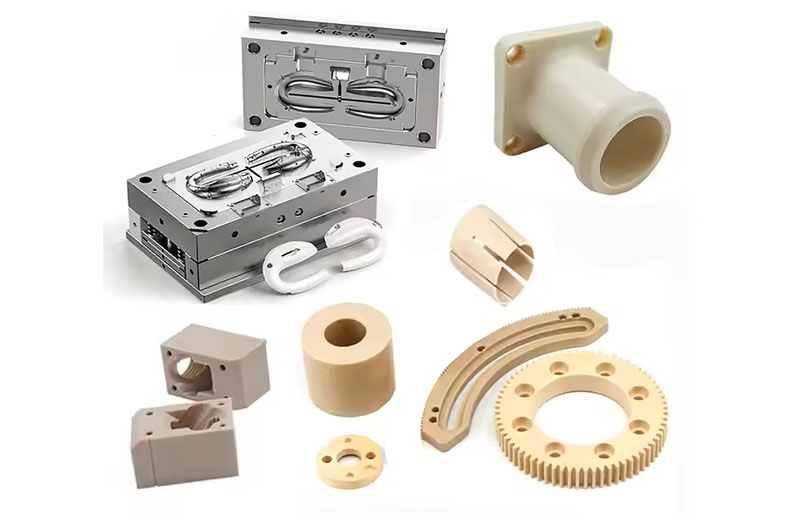

Peek (polyether ether ketone) is widely considered as one of the best thermoplastic materials on the market. Peek is a semi crystalline thermoplastic with excellent wear resistance, chemical resistance and hydrolysis resistance. In many cases, additives are not required. Peek injection molding products have been widely used in aerospace, automotive industry, electronic and electrical, medical machinery and other fields.

The PEEK injection molding temperature of PEEK is approximately between 320 ° C and 390 ° C; Drying temperature 160~185, 5H~8h; The temperature of the injection mold is 140~180. The molding temperature of this material is too high, which can cause serious damage to the screw. When setting the screw speed, the speed should not be too fast. After the molding is completed, the screw should be quickly cleaned with PE wax in a timely manner. The PEEK material should not be left on the screw, otherwise the damage to the raw materials during the secondary heating of the internal structure will be more serious. Choosing PEEK material for injection molding screws requires high-quality alloy screws.