Metal machining and specifically milling are widespread in modern prototyping techniques. Prototype manufacturers tend to maximize their equipment capabilities in regards to technology. One of the methods that have become popular in recent years is helical milling.

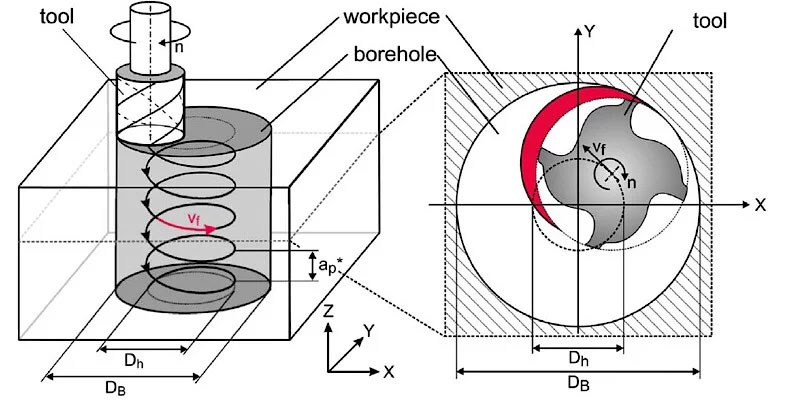

Helical milling is an alternative hole-making process. This process involves an endmill that follows a helical trajectory to achieve a high-quality bore. It offers a lot of advantages compared to conventional drilling and it can downright replace boring machines, which is always advantageous for prototyping shops as they really want to avoid buying lots of equipment. (Ha, not saying that they are dull, they are quite sharp actually, wait… they are boring and sharp at the same time. This wordplay is killing me). Helical milling can be used to create bores of practically any form, the cutting force is lower, tool wear as well and the achievable quality can be quite high.