Sheet metal technology details and precautions

- Bending parameters

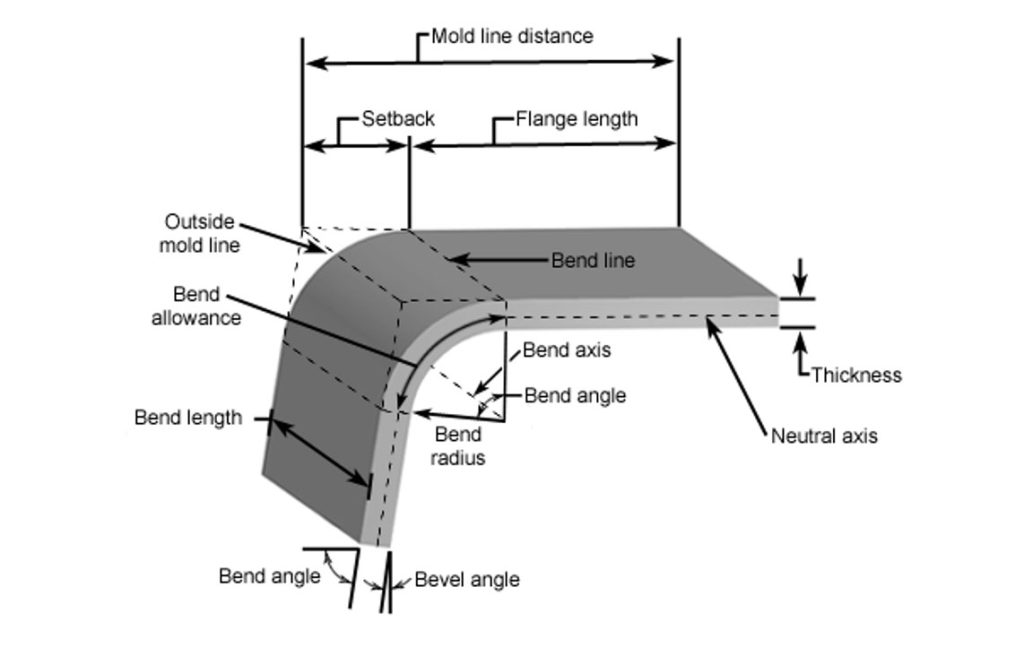

During the bending process, multiple parameters need to be controlled to ensure the quality of the molding. Including bending line, outer mold line, flange length, parting line distance, indentation, bending axis, bending length, bending radius, and bending angle. The selection and calculation of these parameters are crucial for ensuring the accuracy and consistency of the parts.

- Neutral axis and K coefficient

The neutral axis is a boundary line inside the metal sheet, on which it is neither subjected to tension nor pressure, and therefore its length remains unchanged. The K coefficient is a parameter that describes the position of the neutral axis, which is equal to the ratio of the neutral axis distance to the material thickness. The value of the K coefficient is influenced by various factors such as material, bending operation, and bending angle.

- Rebound and compensation

During the bending process, due to residual stresses inside the metal sheet, the sheet will experience a certain degree of rebound after bending. In order to obtain the required bending radius and angle, it is necessary to excessively bend the sheet and precisely control the rebound amount. This usually requires experimentation and experience to determine the appropriate rebound compensation value.

- Mold and tool selection

The selection of molds and tools is crucial for the success of sheet metal forming processes. The material, size, and shape of the mold need to be determined based on the production quantity, sheet metal material, and degree of bending. The coordination between the punch and the mold also needs to be precisely adjusted to ensure the accuracy of the bending angle and shape.