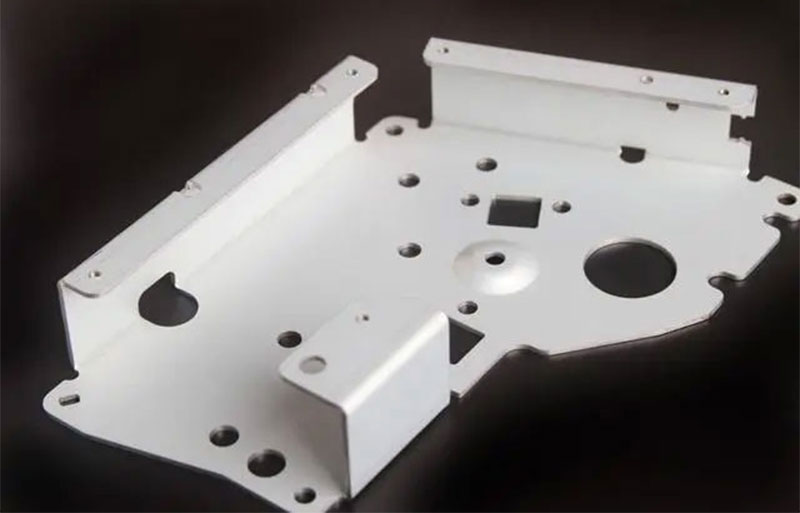

Sheet metal manufacturing is a valuable prototyping and production method used to manufacture sturdy functional components such as panels, brackets, and casings.

However, unlike other manufacturing technologies, sheet metal manufacturing actually involves many different processes, all of which manipulate sheet metal in different ways. These different processes may involve cutting metal sheets, shaping them, or connecting their different parts together.

This guide focuses on the main sheet metal manufacturing processes and explains their working principles and applications.

What is sheet metal processing?

Sheet metal manufacturing is a set of manufacturing processes that successfully process sheet metal into functional components. For this guide, we divide the process into three categories: cutting, deformation, and assembly.

Common sheet metal materials include steel, stainless steel, aluminum, zinc, and copper, with specifications typically ranging from 0.006 to 0.25 inches (0.015 to 0.635 centimeters). Thin specifications are more ductile, while thicker specifications may be more suitable for heavy-duty parts with severe applications.

For partially flat or hollow parts, sheet metal manufacturing can become an economically efficient alternative to processes such as casting and machining. The process is also fast and generates minimal material waste.

Sheet metal manufacturing is widely used in industrial and consumer parts, as well as professional industries such as automotive, aerospace, energy, and robotics.

Sheet metal processing: cutting

One of the three main methods of manipulating sheet metal is to cut it. In this sense, sheet metal manufacturing can be considered as a subtractive manufacturing process (such as CNC machining), as usable parts can be manufactured by simply removing material parts.

Manufacturers can use various machines to cut sheet metal, some of which are unique to sheet metal manufacturing.

One of the key methods for sheet metal cutting is laser cutting. Laser cutting machines use powerful lasers enhanced by lenses or mirrors. It is a precise and energy-saving machine suitable for thin or medium-sized metal plates, but may be difficult to penetrate the hardest materials.

Another sheet metal cutting process is water jet cutting. Water jet cutting is a sheet metal manufacturing method that uses high-pressure water jets (mixed with abrasive materials) to cut metal. Water jet cutting machines are particularly suitable for cutting low melting point metal sheets because they do not generate heat that may cause excessive deformation of the metal.

The third sheet metal cutting option is plasma cutting. The plasma cutting machine creates an ionized gas electric channel, forming a hot plasma jet that can even easily penetrate thick metal plates. Although not as accurate as laser or water jet cutting machines, plasma cutting machines are fast, powerful, and have low setup costs.

These three cutting machines can be used for materials other than sheet metal, but there are also some technologies that are only used for sheet metal manufacturing.

For example, the stamping process (sometimes referred to as punching) uses punches and molds to create precise holes on sheet metal. The metal plate is placed between two components, and the punch forces itself through the metal to reach the mold. During the stamping process, the removed material from the stamped circular parts is turned into waste, but these circular parts can also be used as new parts: this is called cutting.

When creating many holes, similar devices can be used to pierce the metal plate.

Sheet metal processing: bending

Another major category of sheet metal manufacturing processes is sheet metal bending. This set of processes involves countless methods to modify and manipulate sheet metal without cutting into it.

One of the main deformation processes is sheet metal bending. Using a machine called a brake, a sheet metal company can bend sheet metal into V-shaped, U-shaped, and channel shapes, with a maximum angle of 120 degrees. Thin sheet metal specifications are more prone to bending. The opposite can also be done: sheet metal manufacturers can remove horizontal bending from strip sheet metal parts through a debending process.

The stamping process is another deformation process, but it can also be considered as a subcategory of its own. It involves the use of hydraulic or mechanical stamping machines equipped with tools and molds, which operate similarly to stamping – although material removal may not necessarily be necessary. Stamping can be used for specific tasks such as curling, drawing, embossing, flanging, and edging.

Spinning is a sheet metal manufacturing process that, unlike other deformation techniques, uses a lathe to rotate the sheet metal while pressing it onto a tool. This process looks similar to CNC turning or even ceramic spinning, and can be used to create circular sheet metal parts such as cones, cylinders, etc.

Less common sheet metal deformation processes include wheel forming, which is used to create composite curves in sheet metal, as well as rolling, where the sheet metal is fed between a pair of rollers to reduce its thickness (and/or increase thickness consistency).

Some processes fall between cutting and deformation. For example, the process of sheet metal expansion involves cutting multiple slits on the metal and then pulling the sheet metal apart like an accordion.