By the end of the initial design stage, designers have generally gone through a lengthy process of elimination to pinpoint the exact design they want to move forward with. However, at this point in the engineering design process, the initial design is still far from a functioning design.

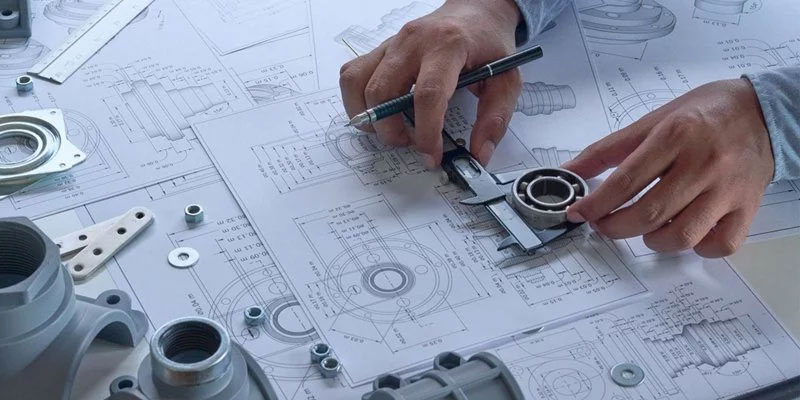

Therefore, the detailed design and optimization stage bridges the gap between conceptual and functional design. First, the initial design will add requisite details. Dimensions are finalized, materials are chosen, tolerances are determined, and assembly setup/constraints are defined. These are hardcore mechanical design activities that ensure the functionality and safety of an engineering design.

Engineers use engineering drawings to consolidate and communicate all this information within and across teams. After design, an optimization study may also be performed. This is a good design and engineering practice. It aims to maximize the performance of the product by finding the best configuration of design inputs (dimensions, orientation, engineering fits, etc.).