With the increasing global demand for energy conservation and emission reduction, lightweighting of automobiles has become an important trend in industry development. In this context, magnesium alloy die-casting parts are gradually becoming the new favorite in the automotive manufacturing field due to their unique advantages.

Advantages of magnesium alloys: Magnesium alloys are known for their low density, high strength, and good thermal stability, making them an ideal material for achieving automotive lightweighting. Compared to traditional steel and aluminum alloys, magnesium alloys reduce weight by about 30% while maintaining excellent mechanical properties and durability, providing stronger power performance and higher fuel efficiency for automobiles.

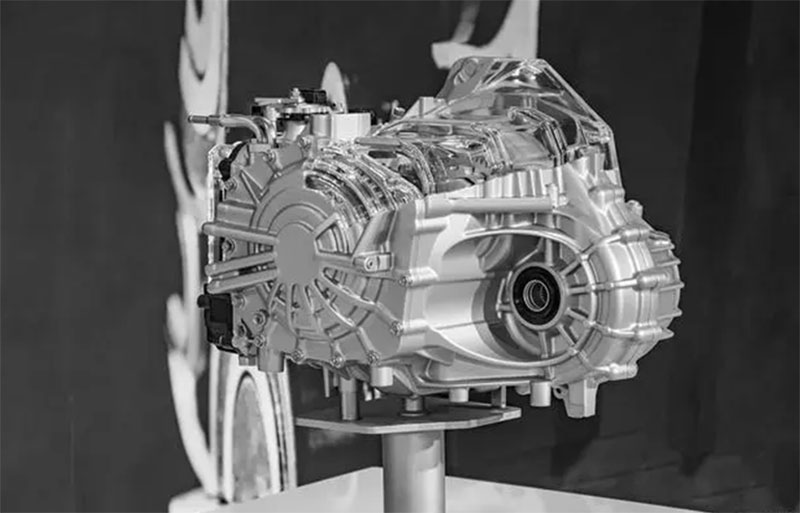

Application of Die Casting Technology: Die casting technology is a manufacturing process that injects molten metal into a mold and rapidly cools and solidifies it. It can produce metal parts with complex shapes, high precision, and high quality. In the automotive field, die cast magnesium alloys are widely used in key parts such as engine components, transmissions, body structures, and wheel hubs.

The application of magnesium alloy die-casting parts not only promotes the process of automotive lightweighting, but also brings higher energy efficiency and lower emissions to the automotive industry. With the continuous advancement of technology and further cost reduction, we have reason to believe that magnesium alloys will play a more important role in future automotive manufacturing, contributing to the realization of green travel and sustainable development.