There are three main stages for tooling manufacture: prototype tooling, bridge tooling, and production tooling.

Prototype Tooling

The first step in the tooling manufacturing process is prototype tooling. This entails making molds and tools to create prototypes or small batches of products. These are generally single-use tools that are crucial for testing and confirming the design before mass production.

Bridge Tooling

Bridge tooling serves as a transitional stage between the end of prototype development and the start of production tooling. Compared to production tooling, it is less robust. It doesn’t require a large investment and can be constructed more rapidly.

Thus, bridge tooling is used by several manufacturers to facilitate the ramp-up of volume. It is more often used to refine the manufacturing process and acquire a comprehensive understanding of product design.

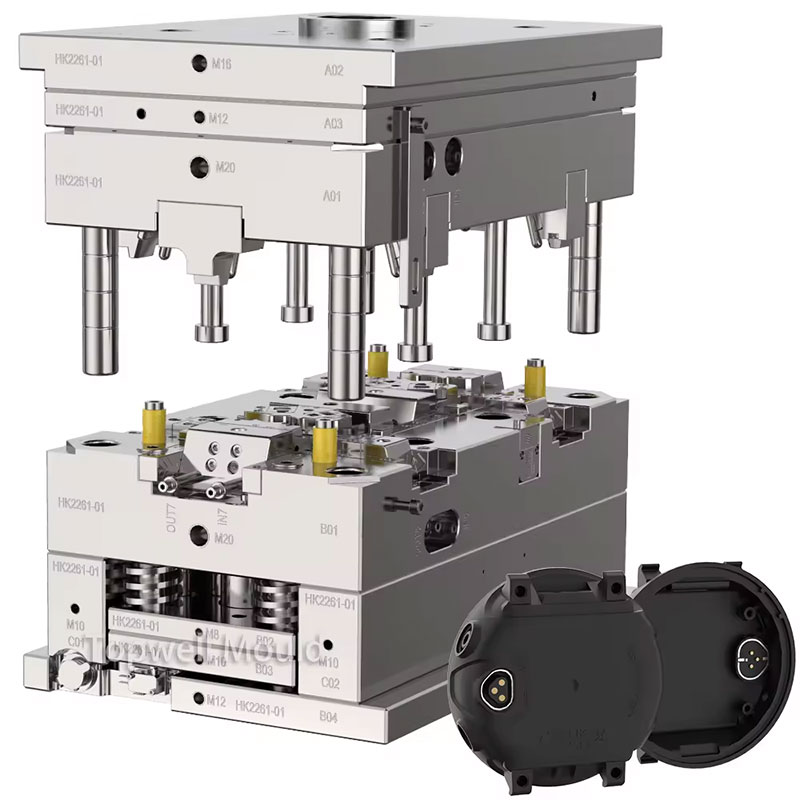

Production Tooling

The production tooling phase is where the final product is fabricated and tested. This phase is important as it sets a great ground for large-scale, mass production. As a result, this type of tooling is designed for long-term use and it ensures the tooling can produce parts to the correct specification and standards.

However, it requires a substantial investment of time and resources. Nonetheless, it guarantees efficiency and cost-effectiveness in high-volume production.